Studying the Effect of Using Ultrasound Vibration on the Reproduction of Detail and Surface Hardness of Dental Stone Models

Ali M. Aljafery1, Mohammed Alkafagy2, Zena J. Wally1*, Athraa Mohammed Dheyaa3, Raja’a M. Almusawi1, Julfikar Haider4

1Department of Prosthodontic Faculty of Dentistry, University of Kufa, Najaf, Iraq

2College of Dentistry, the Islamic University, Najaf, Iraq

3Department of Pharmaceutics and Pharmaceutical Chemistry, College of Pharmacy, University of Alkafeel, Najaf, Iraq

4Department of Engineering, Manchester Metropolitan University, Manchester, UK

*Corresponding author. E-mail: zinah.alnuaimi@uokufa.edu.iq

Received: Aug. 06, 2022; Revised: Oct. 11, 2022; Accepted: Nov. 29, 2022; Published: Nov. 30, 2022

Citation: A.M. Aljafery, M. Alkafagy, Z.J. Wally et al. Studying the effect of using ultrasound vibration on the reproduction of detail and surface hardness of dental stone models. Nano Biomedicine and Engineering, 2022, 14(3): 263–271.

DOI: 10.5101/nbe.v14i3.p263-271

Abstract

Background: The accuracy of surface production details in the dental models determines the success of the dental prosthesis in clinical application.

Aim: This in vitro study aims to compare between dental stone models produced using two types of techniques for pouring the addition silicone impression.

Method: The control group was poured using the conventional vibration technique at a vibration

frequency of 3000 cycles/min and the experimental group was poured by an ultrasound vibration

technique at a frequency of 28 kHz in order to assess the difference in pouring techniques in terms of reproduction of details and surface hardness. A stainless steel die, prepared based on the ISO 6873, was employed to fabricate samples for evaluating the surface details. Fisher’s exact test scoring scale was employed to qualititatively assess the reproduced surface details. Vickers hardness was measured to evaluate the surface hardness of cylindrical stone samples poured by the two different techniques.

Results: The results indicated that the reproduction of details of the stone samples poured by the

ultrasound vibration technique were not significantly different (P > 0.05) in comparison with that

poured by the conventional vibration technique. However, the surface hardness was significantly

enhanced (P = 0.04) by the ultrasound vibration pouring technique.

Conclusion: Although the application of ultrasound vibration during dental cast fabrication did not provide any significant clinical advantages in terms of surface reproducibility, it could significantly improve the surface hardness compared with the traditional vibration technique.

Keywords: Detail reproduction; Surface hardness; Dental stone; Addition silicone impression;

Gypsum cast; Ultrasound vibration

Introduction

Fabrication of successful dental appliances requires a high degree of accuracy of the impression and cast materials to reproduce the natural teeth and associated oral structures. Dimensional stability of gypsum materials is a key factor of producing well-fitted dental prostheses with optimal functional and aesthetic properties [1]. The gypsum products including type IV and type V die stones from either synthetic or natural plasters, are commonly applied in dentistry [2]. Ease of handling and cost-effectiveness make gypsum materials extensively used for creating the study models and in many dental laboratory procedures [1,3]. The main disadvantages of gypsum products are the voids that may occur on the surface (or subsurface) of cast models leading to poor fracture toughness, dimensional variability and technical sensitivity [4]. Pores present on the surface showed to delay laboratory processing, inaccurate anatomical replication (dimensional changes) and low wear resistance [5,6]. It was alleged that the dental plaster could not reproduce all details observed in different impression materials [7].

To overcome the above mentioned issues, various approaches have been progressed and utilised in the clinic, either to decrease the setting time such as the addition of potassium sulfate/powdered gypsum and regulation of water temperature to reduce porosity, improving detail production and mechanical properties by using vacuum machine or vibrator [1,8]. These efforts significantly enhanced the mechanical properties of the gypsum models; however, further enhancement is still demanded by the dentistry professionals.

Gypsum (CaSO4.2H2O; Calcium sulfate dehydrate), a mineral extracted from mines, has been used in dentistry for decades to make primary models, which are needed in the fabrication of many prostheses and restorations. Particle size of gypsum influences the physical and mechanical properties of manufactured models [1,8]. According to ISO standard, dental gypsum products classify into impression plaster (type I), dental plaster, model (type II), dental stone, die, model (type III), dental stone, die, high strength, low expansion (type IV) and dental stone, die, high strength, high expansion (type V). This classification is made based on the applications compositions or formulas. The dental stone is usually used for preparing models and impression plaster for taking primery impression. A specific morphology is achieved by mixing calcium sulfate hemihydrate gypsum powder (CaSO4·1/2H2O) with water, and the subsequent mixture is poured into an impression/designed mold and then let to set [9,10]. The texture of the gypsum surface produced by dental impressions is critical for precise diagnosis and treatment plans and a high-quality prostheses productions [11,12]. The accuracy of casting depends on some factors such as impression material and its fabrication technique, accuracy of die and waxing as well as casting procedures [13,14]. Regarding the conventional molds technique, and during investing the acrylic denture base resin, dental stone is still the best choice for investing procedure [15]. Park and Shin concluded that the conventional method of fabrication of dies was more dependable than the novel digital techniques such as 3D printers [16]. This could be due to the fact that the digital scanning might not fully capture the details [4] or different 3D printers having different working principles and materials used. Type IV dental stone as a die material is more commonly used compared with the epoxy and polyurethane resins [17].

There are changes in gypsum properties, such as setting expansion, mechanical properties, and detail reproduction ability. In addition to inconvenient processes or preparation of the ingredients, these approaches are still suboptimal. Lately, dental stone with fast-setting and anti-foaming characteristics has become accessible by adding optimized ingredients (i.e., potassium sulfate, cyclic siloxane [10], and polycarboxylate [18]) or polymer coating technology (acrylic polymer coating) to the gypsum powder, which provides the ability of fast-setting and enhanced dispersion with decreasing bubble formation during setting [10]. The cocktail shaking method can also be used to mix this product, providing a more suitable methodology to enhance the reproducibility in fabricating dental gypsum-based products by even inexperienced clinicians. Traditional impressions and digital scanning of stone models have been used excessively in dental clinics. Owing to the continuous evolution of direct digital oral scanning to enhance the accuracy and reduce the problems of time and cost, digital dental technologies such as CAD/CAM, 3D printing, and digital scanning/impression systems are continuously developing. Quick set dental gypsum free of the bubble is critical to get a fast oral anatomy recovery with customised/digitalised dental restoratives/prosthodontics [19–22]. However, the high cost of the hardware and software and lack of expertise in using digital devices limit their use. Therefore, investigations on new dental gypsum compared with other products are required to evidence its clinical efficiency [10].

The stone die should possess sufficient strength and hardness in order to resist deformations and abrasion which may occur due to scraching force that applied on the surfaces [23,24]. In fact, dental stones have low fine details reproduction, low abrasion resistance and low desired strength when used in complicated prosthodontics procedures [25]. In dental prosthesis fabrication, the dental cast should have enough strength to save the details of the surface intact due to subjecting to many steps of processing.

The requirement for high quality and durable prosthetic models has encouraged the prosthodontic specialists to explore alternative materials and fabrication techniques. The vast majority of the literature focused on impression materials and their preparation. However, other areas such as characteristics of die materials, poring techniques, pouring time, and digital model fabrication needs to be considered. Comparatively less attention was given in the literature on the model fabrication technique. To the best of the authors’ knowledge, none of the previous studies have measured the effect of using ultrasound vibration on the quality characteristics of the dental stone models. Therefore, the current study presents a comparison between the dental stone models fabricated by conventional vibration and ultrasound vibration during pouring the impression. The null hypotheses assumed that the ultrasound vibration employed during pouring the impression adversely affects the reproduction of detail and surface hardness of the dental stone models.

Material and Methods

Names, description and material manufacturers used in this study are presented in Table 1.

Table 1 Materials used in this study

Materials | Description | Manufacturers |

Dental stone | Type IV gypsum dental stone | Elite Master, Zhermack, Italy |

Silicon impression material | Addition silicon impression | Elite HD, Zhermack, Italy |

Assessment reproduction of details

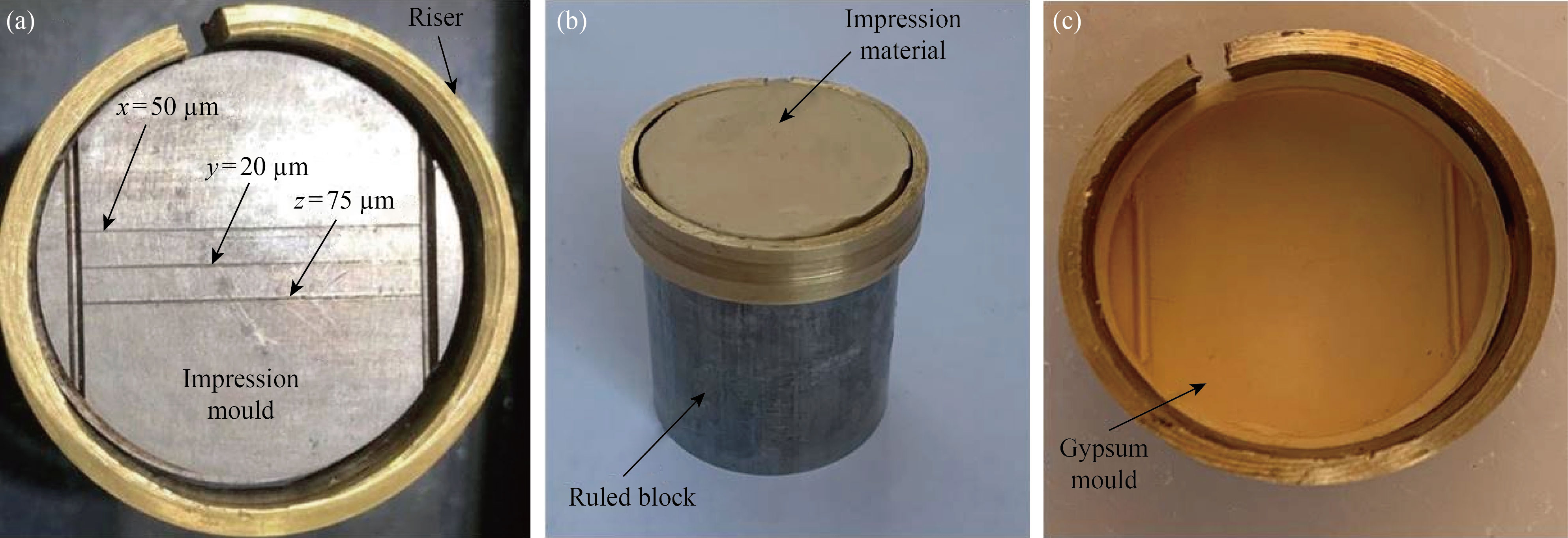

According to the ISO 6873 certification, round stainless steel die with a 30 mm diameter and highly polished surface was prepared to produce samples for compatibility evaluation. Then three parallel lines x, y and z are inscribed respectively with the depths of 50, 20 and 75 μm to assess the surface details reproduction [10] of the stone casts using a silicon impression. The device used for testing consisted of four parts: the ruled block, the impression material mould, the riser, and the gypsum mould (Fig. 1). Addition silicone was used to take an impression for the stainless steel ruled block, which was utilised to fabricate the samples.

Fig. 1 Stainless steel critical die used for reproduction of detail test: (a) Top view of the ruled block with riser ring and impression mould with 3 parallel lines (x, y, z), (b) Ruled block with impression material, (c) Gypsum mould after making impression and removing the riser from top of the ruled block

The impression material mould was put on a ring surrounding the ruled block (named as riser) utilised as a chamber (impression material container) [12]. Before making the samples, cotton gauze soaked with methyl alcohol was used to clean the stainless steel test die surface, and then it was rinsed with distilled water and dried gently with compressed air. Impressions manipulation of the testing mold were made according to manufacturer’s instructions. Measures were considered to spread over same amount of material into the impression mold during sample preparation. The identical seating pattern of the testing apparatus was employed for every impression, to attain consistent sample thickness. A digital microscope (Dino-lite × 200 magnification, Taiwan) at a magnification of ×10 was used for observing the lines produced. The impressions verified that all the lines on the rolled block had been produced on the silicon impression before the dental stone was poured.

Twenty samples were fabricated and separated into control and experimental groups.

Group A (control): The dental stone (Type IV, Elite Master, Zhermack, Italy) was blended following the manufacturer’s instructions (tap water / powder ratio 21 mL / 100g) by using a vacuum mixer (BEGO Motova 300 Vacuum Mixer) for 25 s under a vacuum condition of 0.8 to 1 mm Hg to remove any air bubles and poured the impression by using a vibrator (Vibromaster No. 24122, Bego Bremer Goldschagerel will GmBA and Co., Bremen, Germany). The device was adjusted at a vibration frequency of 3000 cycles/min (low) and 6000 cycles/min (high) by using a knob for 1 min. The amplitude of vibration was supplied in 5 steps, and it remained constant on the device for the selected step.

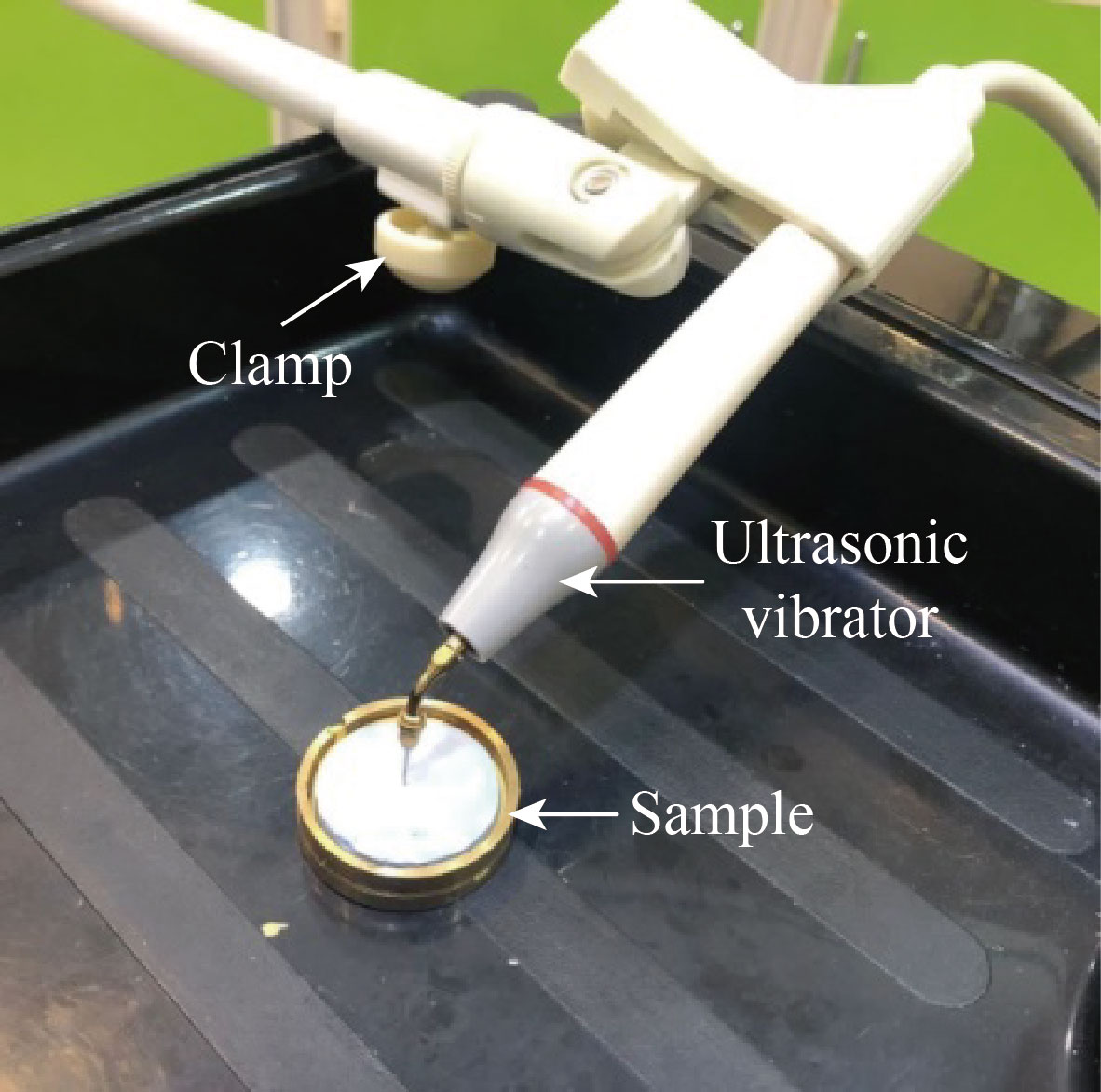

Group B (experimental): The samples were obtained by putting the impression on a flat bench and an ultrasound scaler (Guilin Woodpecker Medical Instrument Co., Ltd., China) handle was fixed on the lab clamp and adjusted so that the tip of the scaler centered in the middle of the impression and 1 mm above the impression surface (Fig. 2). The frequency of the ultrasound vibration was adjusted to 28 kHz for 1 min.

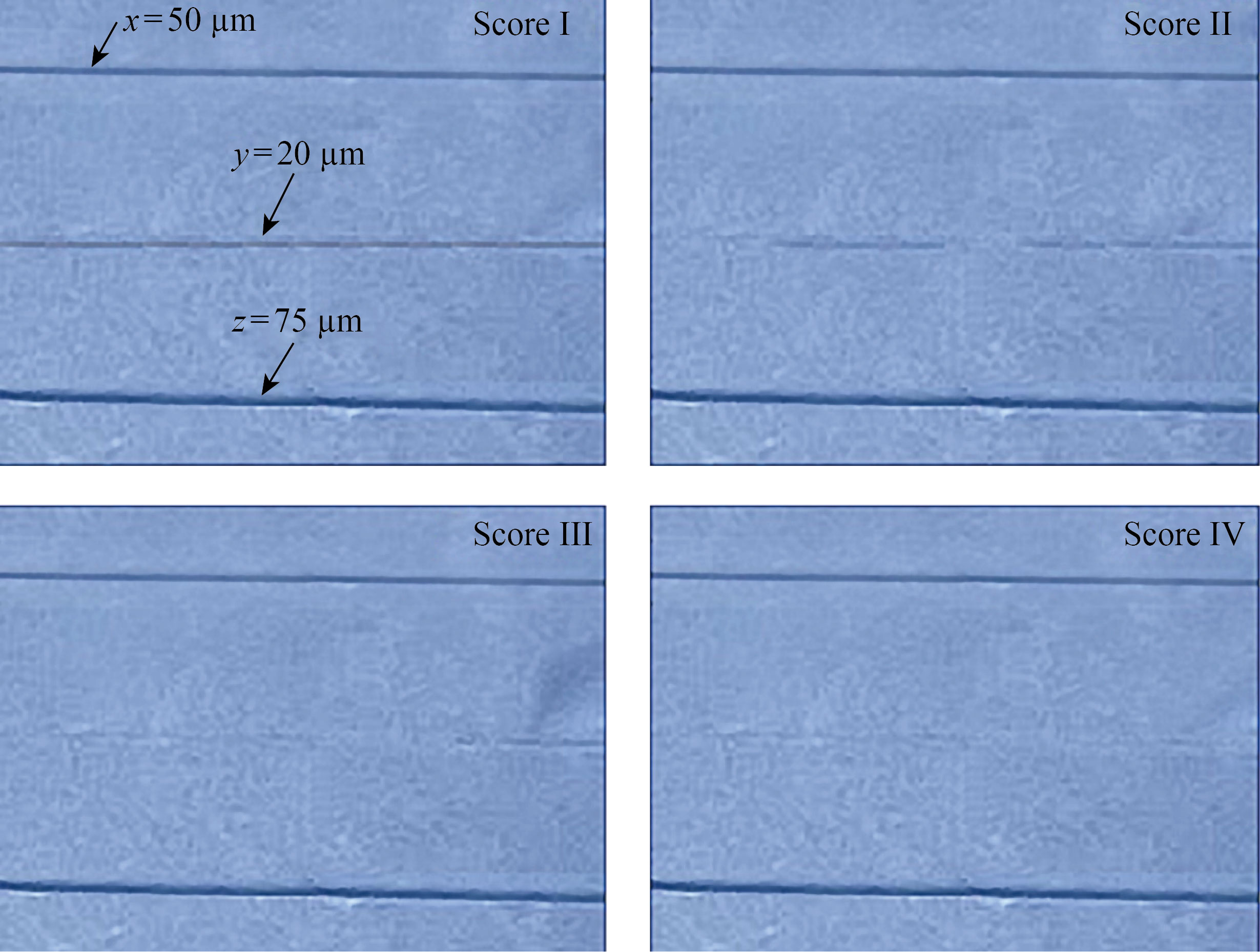

Fig. 2 Installations of ultrasound scaler by lab clamp

One hour after the pouring, the samples were retrieved from the impression and kept within the laboratory conditions (23℃ ± 2℃ with a relative humidity of 23% ± 3%). A total of 20 samples were allocated to the experimental and control groups (n= 10). The samples were analyzed with the aid of a stereomicroscope (magnification ×10) with low-angle light to discarded the ones with any pores, defect, or cracks and fixed position for both the microscope and the samples. All the samples were evaluated at one time and scan done in the middle area (10 mm) of 3 lines x, y, and z (rectangular section). The lines produced were observed under the microscope (magnification ×10) and scores from I to IV were assigned to each sample (Table 2) [26]. All the samples were observed by a single investigator. To avoid any bias in the measurement process, the samples were marked with special codes, which were unknown to the operator performing the measurements.

Table 2 Fisher’s exact test scoring scale for the samples [27]

Score number | Score description |

I | Clear and sharp reproduction of the 20 µm line over its full 25 mm length indicating the best surface appearance. |

II | Clear reproduction of the 20 µm line over half of its full 25 mm length while smooth but not sharp reproduction over the full length. |

III | Clear reproduction of the 20 µm line over less half of its full length while visible but blemished, rough, and/or not sharp over its full length. |

IV | No reproduction of the 20 µm line over its full length but it is rough, blemished, and/or pitted indicating the worst surface appearance. |

Measuring surface hardness

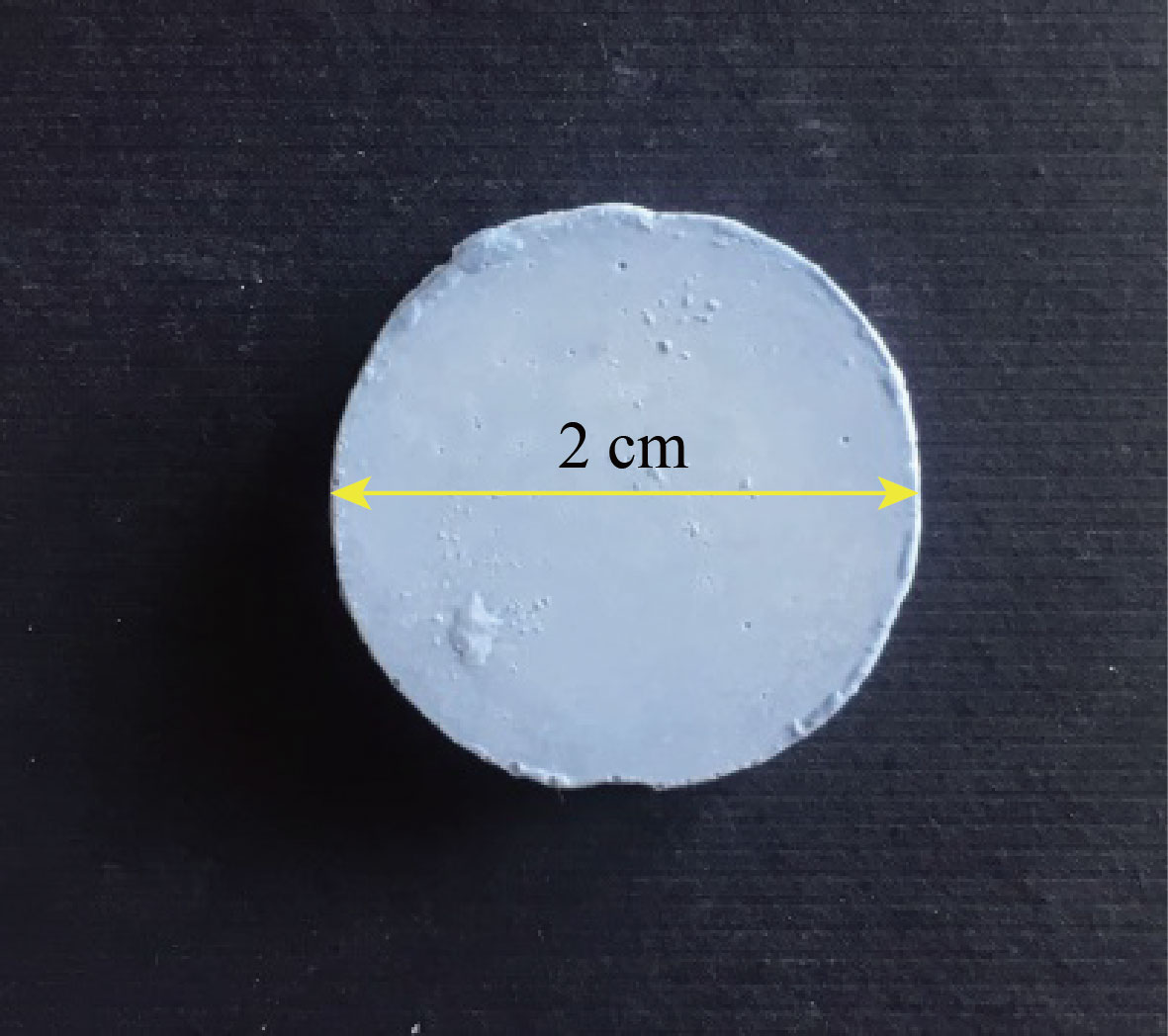

Vickers’ hardness (VH) test was used due to its extraordinary ability to diffrentiate between highly stiff materials. 20 cylindrical PVC tubes, with 2 cm diameter and 1 cm height, were employed to get 20 cylindrical sample from stone. Then with sticky wax, the tubes were attached to glass slabs for production of a smooth surface on the base of the stone samples (Fig. 3).

Fig. 3 Vickers hardness measurement sample

Again the samples were divided into two groups.

Group A (control): Ten samples were obtained by pouring the mold with dental stone and using the conventional vibration technique.

Group B (experimental): Ten samples were obtained by pouring the mold with dental stone and using the ultrasound vibration technique.

After one hour of pouring, the samples were pulled out from the PVC tubes and preserved in laboratory conditions (23℃± 2℃ with a relative humidity of 23% ± 3%). After 24 h, the samples were divided into the experimental and control groups (n = 10). All casts were analyzed with the aid of the stereomicroscope to eliminate any sample with any surface defect. Additional casts were made to replace the defective ones.

The hardness measurement of the surface produced against the glass slab of the experimental and control samples without polishing was carried out by using a microhardness Vickers scale (Zweick, Germany) by an experienced operator, who did not have any prior knowledge about the samples. According to the Vickers scale, a 2000 GF (gram-force) load was applied to the samples with a diamond pyramid-shaped indenter for 15 s at a loading rate of 30 µm/s. Then, the dimensions of the depressions produced were measured under the photomicroscope connected to the hardness testing machine at ×10. This process was repeated at three points on the sample base, and then the mean of the three readings was considered as the Vickers hardness number.

Statistical analysis

The reproduction of detail and surface hardness data showed normality (Shapiro-Wilk; P≥0.05) and homogeneity of variance (Levene; P ≥ 0.05). Statistical analysis was carried out using the IBM SPSS Statistics version 20.0 (IBM Corporation, Armonk, NY, USA). Distribution of stone casts with varying scores for reproduction of detail levels was tested for significant differences with the Fisher’s exact probability test while, the surface hardness results were analyzed by a t-test. For comparison between two groups, independent sample t-test was applied to identify significancant difference of the experimental group with the control group, where P > 0.05 indicates non-significant (NS), 0.05 ≥ P > 0.01 significant (S), and P ≤ 0.01 highly significant (HS). A 95% confidence level was used to consider whether the results were significant or not.

Results

Results on reproduction of details

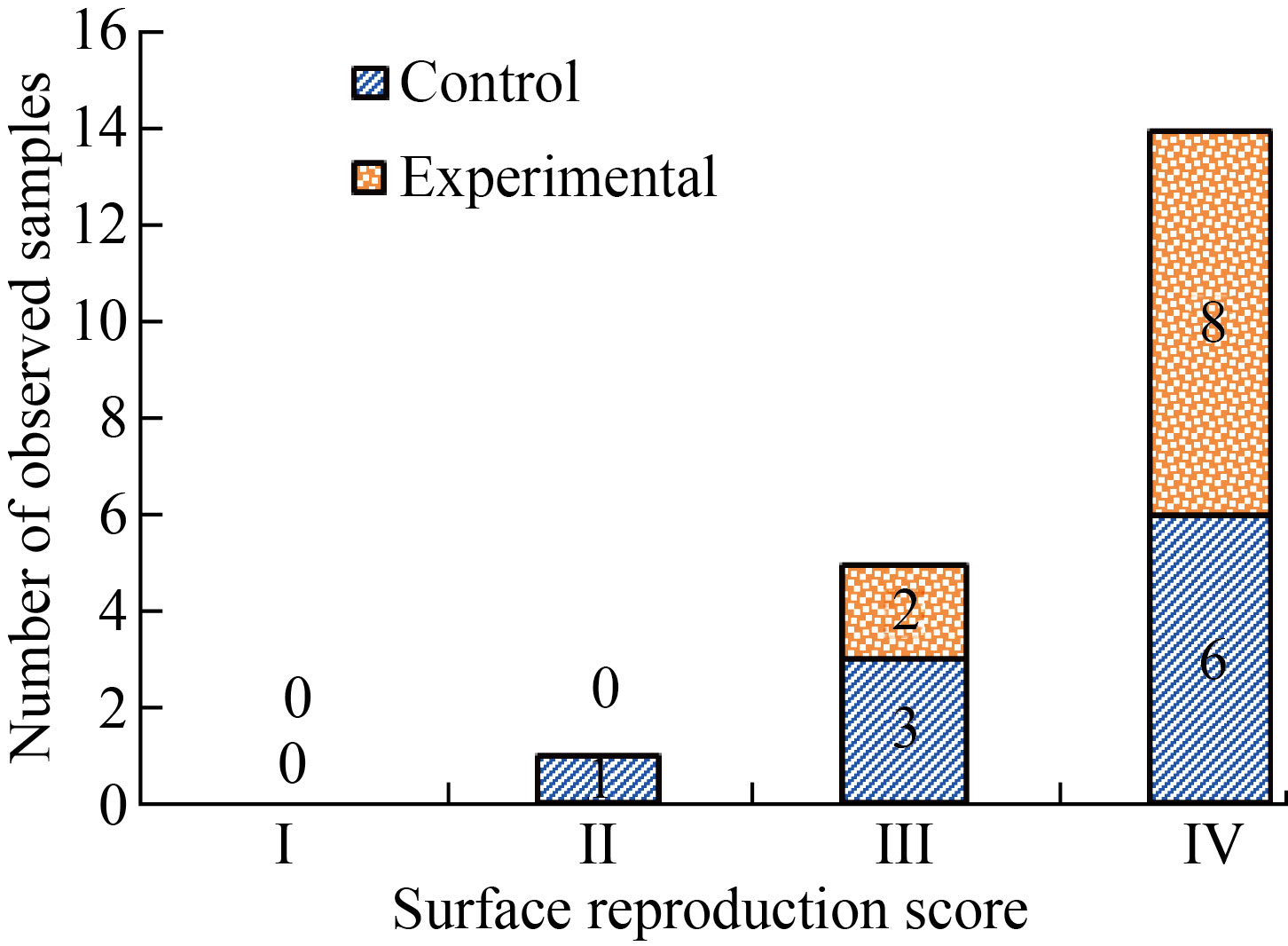

The representative images of the detail reproduction of the stone samples are shown in Fig. 4. The distribution of the stone samples according to the reproduction of detail grading is shown in Table 3. The Fisher’s exact probability test did not show any significant difference between the stone samples produced by using the ultrasound vibration and conventional vibration pouring techniques (P > 0.05). Figure 5 presents the surface reproduction grading graphically.

Fig. 4 Representative images of surface details reproduction grading for Score I, Score II, Score III and Score IV

Table 3 Distribution of stone samples according to reproduction of details grading

Group | Score | Fisher’s exact test | ||||

I | II | III | IV | Value | Exact sig. (2-sided) | |

Control | 0 | 1 | 3 | 6 | 1.478 | 0.628 |

Experimental | 0 | 0 | 2 | 8 | ||

Fig. 5 Surface details reproduction grading for the 20 samples from control and experimental groups (Scoring scale definitions for the samples are presented in Table 1)

Surface hardness results

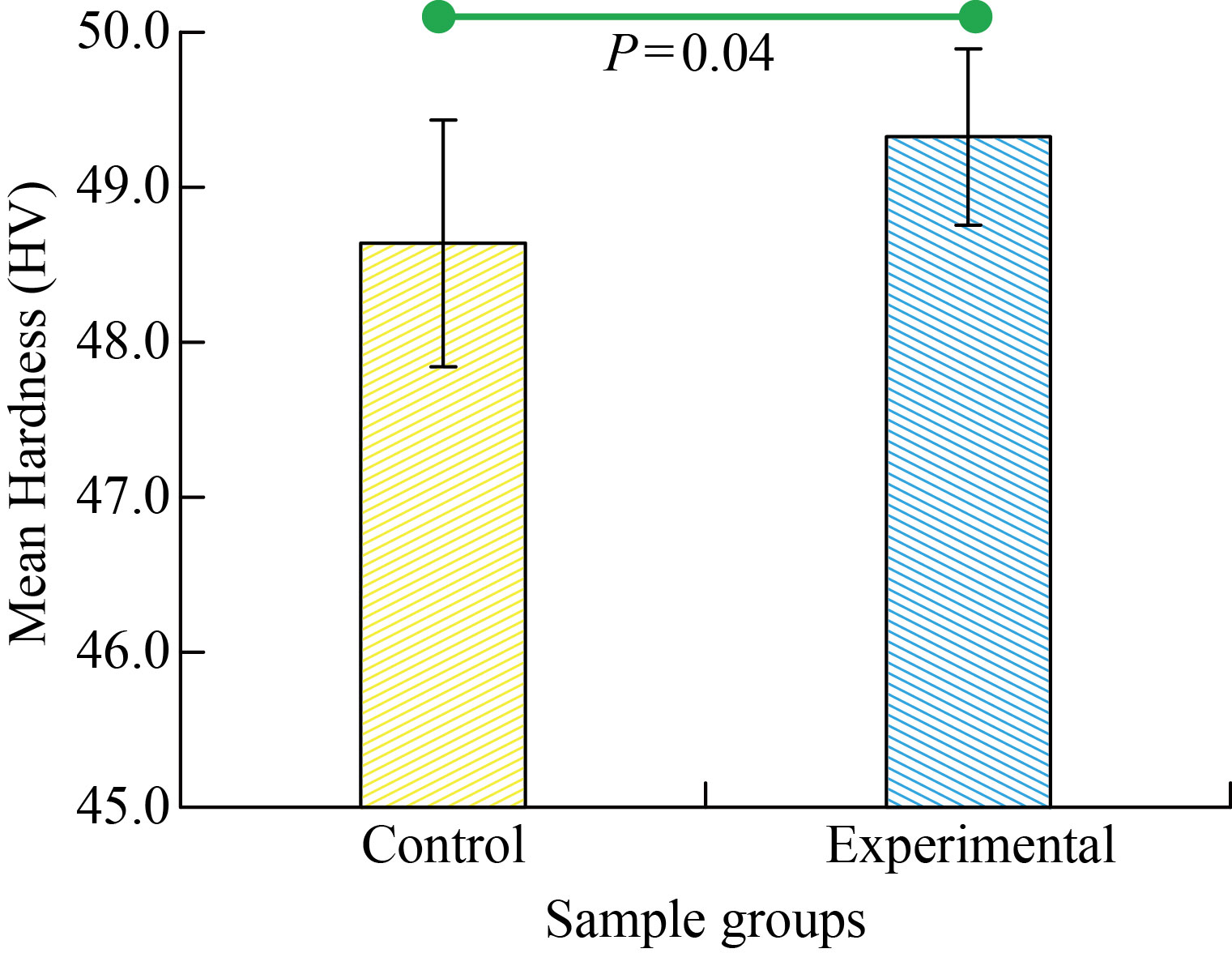

The results of Vickers hardness test are shown in Fig. 6. Stone samples produced by using the ultrasound vibration pouring technique had higher hardness values than those produced by using the conventional vibration pouring technique. According to the t-test results, experimental samples showed a significant increase in surface hardness when compared with the control group (Table 4).

Fig. 6 Surface hardness values for the experimental and control groups (The horizontal line connecting the two bars indicates statistically significant difference)

Table 4 Comparison of surface hardness between the two tested groups

| t-test | ||||

Group | Number | Mean HV | SD | t | P |

Control | 10 | 48.638 | 0.795 | -2.22 | 0.04 |

Experimental | 10 | 49.325 | 0.568 | ||

Discussion

The materials for fabricating dental models must possess a number of characteristics including dimensional accuracy, capability of adequate reproduction details, abrasion resistant, high surface hardness, sufficient flexural strength, compatible with the impression material, and non-toxic [28, 29]. Many efforts were made in the literature to improve the reproduction of fine details and strength properties of gypsum product models by adding different filler materials to the impression or gypsum products.

In the present study, impressions for the test samples were obtained using the addition silicone. Because of its excellent dimensional stability [30], as well as the vacuum mechanical mixing and ultrasound vibration technique used, the mechanised manipulation leads to a more homogenous mixing. As stated by American Dental Association (ADA) specifications, the test methods of the present study are acceptable internationally to investigate linear dimensional changes and detail reproduction possibility of the impression and dental stone materials. The detail reproduction capability of a material could be affected by a number of factors including wettability, viscosity, and die stone compatibility [31]. The results of this study revealed that pouring the addition silicon impression samples by using the ultrasound vibration technique showed no significant difference in the reproduction of details grading when compared with

that poured by the conventional vibration technique. The detail reproduction ability was preserved in all the samples without any dependency on the mixing method and conformed with the ISO standard requirements (complete reproduction with scores of 3 at both 50 and 75 µm width lines). Therefore, the first null hypothesis was rejected.

One of the essential features of the stone cast is the hardness of its surface which can directly influence the surface resistance against the abrasion and scratches that can damage it. The surface hardness of different stone types is inversely related to the water/powder ratio; the higher the powder contributed to the mix, the higher the surface hardness [2]. Vickers test is an accepted technique used to measure the surface hardness of metal and other rigid solids [32, 33]. From a practical point of view, only the external surface layer changes were interesting; a load was applied to discover the hardness changes of both control and experimental groups. The high hardness value in dental stones may be due to the low proportion of porosity, which restricts the cracks expansion and changes of linear dimension in the dental model, improving the hardness [33]. However, the results may be justified in decreasing the area of surface tension and raising the water wettability of hemihydrate (dental stone). Therefore, a more rapid rate of crystallisation will take place due to the increased rate of solubility in the hemihydrate. The present study obtained surface hardness values for the two techniques of pouring with the type IV dental stones. The values obtained by pouring the addition silicon impression samples by using an ultrasound vibration technique, compared with those poured by conventional vibration technique, showed significant difference. Therefore, the second hypothesis was also rejected.

In both the control and experimental groups, no instances were found where the 20 µm line not reproduced at all (Score I). One sample only (10%) from the control group reproduced the 20 µm line but not continuously (Score II). Three samples (30%) from the control group reproduced the 20 µm line continuously with rounded edges as opposed to the two samples (20%) from the experimental group. However, the worst reproduction score of IV with 20 µm line continuously reproduced with sharp edges was found for eight samples (80%) in the experimental group in comparison with six (60%) in the control group. The control group showed slightly better performance in the surface details reproduction gradings of Scores II and III with more clear reproduction traces, though this difference was not statistically significant. Therefore, the ultrasonic vibration pouring technique did not positively affect the surface reproducibility. The mean Vickers hardness of the control group (48.638 HV) was significantly higher than that of the experimental group (49.325 HV). Therefore, the ultrasound vibration during cast fabrication could be recommended to be used by the dentists in everyday clinical applications.

Addition silicone materials was used for impression in this study to produce the best surface reproducibility. A comparative study between different impression material (three alginate and four silicone impression materials) concluded that the silicone impression materials produced better surface finish than the alginate ones [30]. In this study, mixing of dental stone powder was carried out under vacuum condition to avoid voids in the cast, which could be a contributing factor to the poor cast accuracy and reduced strength. Ozyemisci-Cebeci and Yorulmaz investigated void formation in three different mixing conditions: hand-mixed, hand-mixed after powder soaking for 1.5 min, and vacuum mixed [34]. The number of voids were recorded and categorized as small and large voids based on two measured diameter ranges of 0.01-0.05 mm and 0.051–0.1 mm. The samples prepared by mixing under vacuum produced significantly less number of voids as compared with the conventional hand mixing. Regarding the number of voids, there was no significant difference when comparing the samples prepared by soaking powder in water and mixing under a vacuum. Furthermore, the vacuum mixing was reported to be beneficial in terms reducing the pore numbers [35].

No studies exactly similar to this investigation was found in the literature. Reddy and Aparna reported that dental stone models produced by changing the vibration frequency of a mechanical model vibrator at 3000 cycles/min (low) and 6000 cycles/min (high), and the number of voids were counted. They reported that higher vibration frequency significantly reduced void formation due to the reduced air entrapment [36]. Similar findings were also reported by Abdullah et al. It was worthwhile to note that a decrease in amplitude reduced the void formation but a reduction in amplitude alone did not show any statistically significant effect in reducing the void counts [37]. Higher energy transfer to mold with higher frequency in combination with appropriate amplitude setting could control the average flow of the gypsum slurry vertically and the rate of spreading in a horizontal direction, which eventually regulates the void formation. The higher hardness and better detailed surface reproduction found in this study with the ultrasonic vibration could be attributed to the smaller number of voids leading to a more compact and rigid model reproduced with small surface features. The frequency and amplitude of vibration were reported to decrease the void formation on the surface of the dental stone cast [36].

More recently, a newly developed Type IV stone (Shake! Mix STONE) is commercially available and as the name implies, mixing is done by handshaking in a plastic container (specially-made) with water a specially-made plastic container with water [35]. Shaking movement transfers greater energy to the mixture and increases interactions between water and stone powder. Better surface reproduction and compressive strength were found compared with other conventional die stones.

Even though careful attention was given in every step of sample production, unavoidable small variability in sample preparation and measurement might contribute to the variation in the results. Furthermore, the results obtained in this study only used one type of die stone and impression materials, therefore the results cannot be generalized for other combination of die stone and impression materials. Further studies on evaluating other mechanical properties for instance compressive strength of the casts made with ultrasound vibration could validate the findings in this study and the relationship between mechanical properties and pore formation can be explored.

The ultrasound vibration pouring technique could provide a method for improving the surface hardness of the commonly used dental stone cast without negatively affecting other physical properties. With this technique, the clinicians do not necessarily need to buy latest high performance materials or equipment since the ultrasound scaler machine is available in every dental clinic which can be used in pouring the impression to fabricate model or cast with improved surface properties.

Conclusion

Within the limitations of the results obtained in this in vitro investigation, the following conclusions can be deduced.

(1) Reproduction of details results of stone samples produced by using an ultrasound vibration pouring technique was not significantly different in comparison with those produced by using the conventional vibration pouring technique.

(2) The surface hardness results of stone samples were significantly improved by using ultra sound vibration pouring technique.

References

[1] K.J. Anusavice, C. Shen, H.R. Rawls. Phılıps’ Science of Dental Materials, 2012.

[2] B.J. Kenyon, M.S. Hagge, C. Leknius, et al. Dimensional accuracy of 7 Die materials. Journal of Prosthodontics, 2005, 14(1): 25–31. https://doi.org/10.1111/j.1532-849x.2005.00007.x

[3] J.M. Paquette, T. Taniguchi, S.N. White. Dimensional accuracy of an epoxy resin Die material using two setting methods. The Journal of Prosthetic Dentistry, 2000, 83(3): 301–305. http://dx.doi.org/10.1016/S0022-3913(00)70132-6

[4] W.J. van der Meer, F.S. Andriessen, D. Wismeijer, et al. Application of intra-oral dental scanners in the digital workflow of implantology. PLoS One, 2012, 7(8): e43312. https://doi.org/10.1371/journal.pone.0043312

[5] S.S. Azer, R.E. Kerby, L.A. Knobloch. Effect of mixing methods on the physical properties of dental stones. Journal of Dentistry, 2008, 36(9): 736–744. http://dx.doi.org/10.1016/j.jdent.2008.05.010

[6] T.J. Lindquist, C.M. Stanford, E. Knox. Influence of surface hardener on gypsum abrasion resistance and water sorption. The Journal of Prosthetic Dentistry, 2003, 90(5): 441–446. http://dx.doi.org/10.1016/S0022-3913(03)00544-4

[7] R.D. Guiraldo, A.F.F. Moreti, J. Martinelli, et al. Influence of alginate impression materials and storage time on surface detail reproduction and dimensional accuracy of stone models. Acta Odontol. Latinoam., 2015, 28(2): 156–161. https://doi.org/10.1590/s1852-48342015000200010

[8] R. Sakaguchi, J. Powers. Craig’s restorative dental materials, 2012. https://doi.org/10.1016/C2010-0-65754-3

[9] G. Fernandez de Grado, L. Keller, Y. Idoux Gillet, et al. Bone substitutes: A review of their

characteristics, clinical use, and perspectives for large bone defects management. Journal of Tissue Engineering, 2018, 9: 2041731418776819. https://doi.org/10.1177/2041731418776819

[10] J.H. Kim, Y.W. Im, S. Oh, et al. Characterization of an anti-foaming and fast-setting gypsum for dental stone. Dental Materials, 2019, 35(12): 1728–1739. http://dx.doi.org/10.1016/j.dental.2019.08.110

[11] P.A. Pandey, D.A. Mehtra. Comparative study of Dimensional stability and accuracy of various elastomaric materials. IOSR Journal of Dental and Medical Sciences, 2014, 13(3): 40–45. https://doi.org/10.9790/0853-13354045

[12] R.D. Patel, M.T. Kattadiyil, C.J. Goodacre, et al. An in vitro investigation into the physical properties of irreversible hydrocolloid alternatives. The Journal of Prosthetic Dentistry, 2010, 104(5): 325-332. http://dx.doi.org/10.1016/S0022-3913(10)60149-7

[13] P. Duke, B.K. Moore, S.P. Haug, et al. Study of the physical properties of type IV gypsum, resin containing, and epoxy Die materials. The Journal of Prosthetic Dentistry, 2000, 83(4): 466–473. http://dx.doi.org/10.1016/S0022-3913(00)70043-6

[14] P. Rajagopal, V. Chitre, M.A. Aras. A comparison of the accuracy of patterns processed from an inlay casting wax, an auto-polymerized resin and a light-cured resin pattern material. Indian Journal of Dental Research, 2012, 23(2): 152-156. https://doi.org/10.4103/0970-9290.100418

[15] R.M. Al Musawi, A.Z. Al Taai, M.T. Al Khafagy. The Effect of using Iraqi Plaster with Type III Dental Stone as Investing Materials on the Vertical Dimension of Occlusion in Acrylic Resin Complete Dentures (a comparative Study). Chemistry and Materials Research, 2015, 7(9): 49–53. https://iiste.org/Journals/index.php/CMR/article/view/25449

[16] M.E. Park, S.Y. Shin. Three-dimensional comparative study on the accuracy and reproducibility of dental casts fabricated by 3D printers. The Journal of Prosthetic Dentistry, 2018, 119(5): 861.e1-861.e7. http://dx.doi.org/10.1016/j.prosdent.2017.08.020

[17] R. Prisco, G. Cozzolino, P. Vigolo. Dimensional accuracy of an epoxy Die material using different polymerization methods. Journal of Prosthodontics, 2009, 18(2): 156–161. https://doi.org/10.1111/j.1532-849x.2008.00399.x

[18] N. Wongkornchaowalit, V. Lertchirakarn. Setting time and flowability of accelerated Portland cement mixed with polycarboxylate superplasticizer. Journal of Endodontics, 2011, 37(3): 387-389. https://doi.org/10.1016/j.joen.2010.11.039

[19] L. Praça, F.C. Pekam, R.O. Rego, et al. Accuracy of single crowns fabricated from ultrasound digital impressions. Dental Materials, 2018, 34(11): e280–e288. http://dx.doi.org/10.1016/j.dental.2018.08.301

[20] B.J. Choi, S. Yoon, Y.W. Im, et al. Uniaxial/biaxial flexure strengths and elastic properties of resin-composite block materials for CAD/CAM. Dental Materials, 2019, 35(2): 389–401. http://dx.doi.org/10.1016/j.dental.2018.11.032

[21] M.L.C. Aragón, L.F. Pontes, L.M. Bichara, et al. Validity and reliability of intraoral scanners compared to conventional gypsum models measurements: A systematic review. European Journal of Orthodontics, 2016, 38(4): 429-434. https://doi.org/10.1093/ejo/cjw033

[22] B. Vandenberghe. The digital patient - Imaging science in dentistry. Journal of Dentistry, 2018, 74(S1): S21-S26. http://dx.doi.org/10.1016/j.jdent.2018.04.019

[23] M.A. Silva, R.P. Vitti, S. Consani, et al. Linear dimensional change, compressive strength and detail reproduction in type IV dental stone dried at room temperature and in a microwave oven. Journal of Applied Oral Science, 2012, 20(5): 588–593. https://doi.org/10.1590/s1678-77572012000500016

[24] V. Narayanan, J. Padmanabhan, R. Chowdhary. In vitro comparison of dimensional stability of stone dies obtained from two elastomers after two treatments. International Journal of Prosthodontics and Restorative Dentistry, 2011, 1(3): 169–173. http://dx.doi.org/10.5005/JP JOURNALS-10019-1031

[25] G.R.R. Lillywhite, F. Vohra. Influence of polyurethane resin dies on the fit and adaptation of full veneer crowns. Indian Journal of Dental Research, 2015, 26(1): 72–76. https://doi.org/10.4103/0970-9290.156814

[26] J. Ywom. Evaluation of accuracy of impression materials with different mixing techniques, 2013. https://scholarsrepository.llu.edu/etd/158/

[27] C.P. Fernandes, N. Vassilakos. Accuracy, detail reproduction, and hardness of gypsum casts produced from silicone impressions treated with glow discharge. The Journal of Prosthetic Dentistry, 1993, 70(5): 457–464. http://dx.doi.org/10.1016/0022-3913(93)90085-3

[28] S. Kreve. Analysis of linear dimensional change of different materials used for casting dental models: Plaster type 4, nanocomposites carbon nanostructures, polyurethane resin and epoxy resin. Journal of Dental Health, Oral Disorders & Therapy, 2018, 9(2): 200–205. https://doi.org/10.15406/jdhodt.2018.09.00359

[29] Z. Wu, X. Lu, X. Wang, et al. Overview of polymeric biomaterials for dental applications. Biomaterials and Materials for Medicine, 2021: 145–176. https://doi.org/10.1201/9781003161981-5

[30] Y.C. Chang, C.H. Yu, W.M. Liang, et al. Comparison of the surface roughness of gypsum models constructed using various impression materials and gypsum products. Journal of Dental Sciences, 2016, 11(1): 23-28. http://dx.doi.org/10.1016/j.jds.2012.11.002

[31] G.H. Johnson, X. Lepe, T.C. Aw. The effect of surface moisture on detail reproduction of elastomeric impressions. The Journal of Prosthetic Dentistry, 2003, 90(4): 354–364. http://dx.doi.org/10.1016/S0022-3913(03)00429-3

[32] B. Darvell. Materials science for dentistry, 2009. https://doi.org/10.1016/C2015-0-05454-5

[33] O.M. Aljubori, A.M.A. Aljafery, R.M. Al-Mussawi. Evaluation the linear dimensional changes and hardness of gypsum product/stone type IV after adding silica nanoparticles. Nano Biomedicine and Engineering, 2020, 12(3): 227-231. https://doi.org/10.5101/nbe.v12i3.p227-231

[34] 34. N. Ozyemisci, M. Yorulmaz. A new dental casting technique for production of void-free dental models. European Oral Research, 2020, 54(3): 119–122. https://doi.org/10.26650/eor.20200098

[35] Y. Nagasawa, Y. Hibino, H. Shigeta, et al. Characteristics of a new dental stone mixed by shaking. Dental Materials Journal, 2020, 39(3): 355-366. https://doi.org/10.4012/dmj.2018-427

[36] N.K. Reddy, I. Aparna. Effect of frequency and amplitude of vibration and role of a surfactant on void formation in models poured from polyvinyl siloxane impressions. Journal of Conservative Dentistry, 2011, 14(2): 151–155. https://doi.org/10.4103/0972-0707.82620

[37] M.A. Abdullah. Effect of frequency and amplitude of vibration on void formation in dies poured from polyvinyl siloxane impressions. The Journal of Prosthetic Dentistry, 1998, 80(4): 490–494. https://doi.org/10.1016/S0022-3913(98)70017-4

Copyright© Ali M. Aljafery, Mohammed Alkafagy, Zena J. Wally, Athraa Mohammed Dheyaa, Raja’a M. Almusawi and Julfikar Haider. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.