Research Article

Flexural Resistance and Impact Resistance of High-Impact Acrylic Resin with Addition of TiO2-Al2O3 Nanoparticles

Ali Mohammad Ali Aljafery *

Department of Prosthodontics, College of Dentistry, University of Kufa, Iraq.

* Corresponding authors. E-mail: alim.aljaafri@uokufa.edu.iq; Tel.: 009647831520636

Received: Dec. 4, 2017; Accepted: Feb. 13, 2018; Published: Mar. 1, 2018

Citation: Ali Mohammad Ali Aljafery, Flexural Resistance and Impact Resistance of High-Impact Acrylic Resin with Addition of TiO2-Al2O3 Nanoparticles. Nano Biomed. Eng., 2018, 10(1): 40-45.

DOI: 10.5101/nbe.v10i1.p40-45.

Abstract

The chemical modification of conventional acrylic resin by butadiene-styrene rubber to get high-impact acrylic resin has not been completely effective due to its potential bad influence on the resistance of bending or flexural and also the toughness of acrylic resin substance for the base of denture. So, to overcome this detrimental effect of rubber modification of acrylic resin, we tried to reinforce it in this research by the addition of titanium oxide and aluminum oxide nanoparticle mixture to the liquid (monomer) of acrylic resin (high-impact) with sonication at 3 wt% (TiO2:Al2O3 ratio1:1) which was then blended with polymer (powder) of acrylic resin using conventional procedure to form nanocomposite. 40 specimen of two groups (20 for each group) according to the performed property, 20 specimens for flexural strength group and 20 specimens for impact strength group were prepared. Each group was divided into two subgroups, control group A: 10 samples of pure high-impact acrylic, and study group B: 10 samples of modified high-impact acrylic resin by 3 wt% nanoparticle mixture. Testing of the flexural strength was examined by flexural testing universal machine (Instron), while testing of the impact strength was examined by impact testing Charpy's machine. The results were gathered from the tests and translated by statistical program (SPSS version 20) for analysis. The flexural strength and the impact strength increased with high significance upon the addition of 3 wt% nanoparticle mixture, according to t-test (Two-Sample Assuming Unequal Variances) and p-value.

Keywords: High-impact acrylic resin; Titanium oxide nanoparticles; Aluminum oxide nanoparticles; Nano composite

Introduction

For about 60 years, acrylic resin or poly methyl methacrylate (PMMA) has been considered as a major employed substance for the fabrication of denture base [1]. However, a lack of enough strength (toughness) makes this material not-perfect [2]. This emerges when accidentally the denture appliance falls down on a tough surface or breaks when submitted to over forces of mastication [3, 4]. The solution lies in improving its mechanical properties. Many trials have been made to improve and modify the flexural strength, impact strength and surface hardness of acrylic resin. One example is a chemical alteration of its structure by copolymerization of acrylic resin with rubber. The phase of rubber conjunction as a co-polymer of butadiene-styrene leads to improving the impact strength, yet the flexural strength decreases and the cost is high [5, 6, 7]. Most recently, much interest has been pointed to the addition of nanoparticles as inorganic materials into acrylic resin to improve its properties. Properties of the polymer nanocomposites are based on the nanoparticles’ type, form and size, in addition to the interaction and concentration with the matrix of the polymer [8, 9]. Results showed that the strength of the conventional acrylic resin with Al2O3 powder increased significantly in its flexural strength and hardness with no negative effects on the surface roughness [10], and various percentages of TiO2 nanoparticles for strengthening of polymethylmethacrylate led to increased flexural strength [11]. Safarabadi et al. improved significantly the mechanical resistance properties including flexural and impact of acrylic resin by the addition of HA/AL2O3 nanoparticles [12]. Sodagar et al. showed the addition of TiO2 - SiO2 nanoparticles had negative effect on the mechanical properties of acrylic resin [13]. Also, the study done by Lee et al. presented that nanocomposite with SiO2 - CaO could be used as an enforcement to poly (methyl methacrylate) (PMMA) due to its positive effect on the mechanical properties [14]. This search was directed to utilizing titanium oxide and aluminum oxide nanoparticle mixture which were incorporated to acrylic resin to produce high-impact acrylic resin /titanium oxide and aluminum oxide nanocomposite, to study the effects of this addition on flexural strength and impact strength and to compare with pure high-impact acrylic resin.

Experimental

Preparation of specimens

Two non-similar plastic patterns were fabricated (Fig. 1) in the wanted dimension and form by utilizing apparatus of laser cutting according to the required test. Flexural strength samples with the dimension of 65 mm length × 10 mm width × 2.5 mm thickness) which was similar to the shape of a bar [15]. The impact strength pattern was similar to the shape of flexural strength pattern but with a dimensions of 80 mm length × 10 mm width × 4 mm thickness [16].

Fig. 1 Samples of cutting plastic for (a) flexural strength and (b) impact strength.

Mould preparation:

The conventional complete dentures processing of water bath technique was used for mould preparation (conventional flasking technique).

Mixing and proportioning of acrylic

The fillers of monomer, polymer and nanoparticles were mixed at certain amounts with certain ratios and percentages, which were employed for the study as illustrated in Table 1. An electronic balance of 0.0001 g accuracy was utilized to determine the required weight.

Table 1 Ratio of mixing of the nanoparticle mixture (TiO2-Al2O3) with acrylic resin

|

Group (by the percentage of nanoparticles) |

Ratio (TiO2 : Al2O3) |

Amount of TiO2-Al2O3 (g) |

Amount of polymer (g) |

Amount of monomer (mL) |

|

Control group (0%) |

0 |

0 |

22 |

10 |

|

Study group (3 wt%) |

1 : 1 |

0.66 (0.33 g 1.5% TiO2; 0.33 g 1.5% Al2O3) |

21.34 |

10 |

Source and characterization of nanoparticles and acrylic resin

Aluminum oxide (Al2O3, size of 20-30 nm) nanoparticles, NS6130 01-123, Germany; Titanium oxide (TiO2, size < 50 nm) nanoparticles, NS6130 01-123, Germany; and Hot cured high-impact acrylic, Vertex, Netherlands.

Addition of nanofillers

To prepare the dough after mixing powder and liquid of acrylic, the measured ingredients of nanoparticles (3w%) were incorporated to the liquid (monomer). The nanoparticle fillers were fully mixed and scattered in the liquid of monomer through a sonication machine for perfect dispersion for about 3 minutes and were dispersed into single nanocrystals [17]. Then monomer with dispersed nanofillers was mixed immediately with the powder of acrylic resin to decrease the nanoparticle accumulation.

Testing procedure of the prepared specimens

Flexural strength

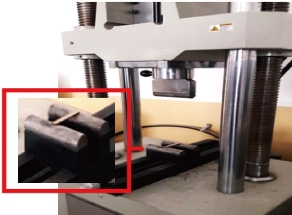

The test was applied through a universal testing machine (Instron) (Fig. 2). Every specimen was placed on the fixture of bending composed of 2 parallel supports with 50 mm apart (between the two supports), and the load was directed with a speed of 1 mm/min by a rod positioned at the center of parallel supports which led to bending till the break occurred. The flexural strength was calculated according to the following formula:

Flexural strength = 3pL / 2bd2,

where p is load of peak, L is length of sample, b is width of sample, and d is thickness of the sample.

Fig. 2 The flexural strength testing machine.

Impact strength

Impact strength test was conducted according to the manner gated by the ISO 179 (Charpy type) impact testing apparatus. The sample was placed horizontally at its terminal ends and hit by free swinging pendulum that was liberated from a height fixed in the middle (Fig. 3). Non-notched sample was used in Charpy impact strength and measured in KJ/m2, according to the following formula:

Impact strength = E / B × D × 103,

where E is energy of impact, B is specimen width, and D is specimen thickness.

Fig. 3 The impact strength testing machine.

Results and Discussion

Testing of flexural strength

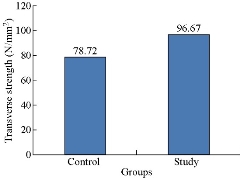

Descriptive data of average (mean), standard deviation (SD), t-test and p-value showing significant difference between the two groups of control and study are listed in Table 2. Table 2 shows that the mean value of the study group was 96.67 N/mm2, higher than that of the control group which was 78.72 N/mm2. The t-test revealed a highly significant difference between the two groups with a p-value of 0.000. The means of two groups were plotted in Fig. 4.

Table 2 Flexural strength statistics

|

Group |

No. |

Mean |

SD |

t-test |

p-value |

|

Control |

10 |

78.72 |

0.541 |

-77.59 -- |

0.00 HS |

|

Study |

10 |

96.67 |

0.492 |

Fig. 4 Flexural strength chart.

Testing of impact strength

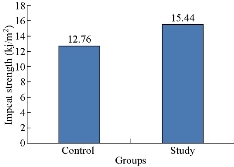

To show the significant difference between the control group and the study group, t-test and p-value were also used, as listed in Table 3. The study group (group B) showed the elevated impact strength mean value as of 15.44 KJ/m2, while the control group (group A) showed the lowest one as of 12.76 KJ/m2. The t-test detected a difference as statistically highly significant between the control group and the study group, with p-value of 0.000. Means of the two groups are plotted in Fig. 5.

Table 3 Impact strength statistics

|

Group |

No. |

Mean |

SD |

t-test |

p-value |

|

Control |

10 |

12.76 |

0.443 |

-7.97 -- |

0.00 HS |

|

study |

10 |

15.44 |

0.967 |

Fig. 5 Impact strength chart.

Improvement of mechanical properties

Throughout history, the strengthening of polymers in history has been by incorporating substances such as oxides of metal [18], metal reinforcements [19] and fibers such as aramid fibers [20]. The form, size and concentration of particle filler in matrix of polymer and intense interface adhesion play a great effect on polymer composite properties [21]. Metal oxide particles sized as tiny as possible are for perfect manipulation. The size of particles utilized in this search was smaller (metal oxides of nanoscale) than that of polymer particles (microscale). Subsequently, the oxide of metal fillers will fill polymer matrix in interstitial spaces of particles to get a heterogeneous admixture leading to the prevention of segment chain displacement of polymers [22]. Moreover, the concentration of metal particles must be preserved low to secure that they will be planted in the matrix of resin [23]. Perfect diffusion of nanoparticles in the monomer could be done by utilizing a sonicatar (sonication machine) which will prevent the agglomeration of nanoparticles [24]. Occlusal stress with acrylic prosthodontic appliance is usually lower than with normal dentition, where the mean of force on acrylic prosthodontic appliance is 40-200 N, while on normal dentition it is 300-3000 N. Hence, when choosing materials, the essential consideration should be of clinical and mechanical performance of this material to withstand flexural and impact stresses [25]. Mechanical properties were improved in the current study. There was a highly significant increase in flexural strength and impact strength when the mixture of nanoparticles was added to acrylic resin (high-impact type). Prospect of clinical success of acrylic appliance increased with enhancing it with nanomaterials rather than adding plasticizers. The value of flexural strength increased with the incorporation of 3 wt% mixture of nanoparticles due to the possible proper diffusion of the extremely fine nanoparticles that allowed them to fill the macromolecular linear polymer chains and the gaps among chains; therefore, macromolecules’ segmental movement functioned as a limited drive to raise the rigidity and the strength of composite resin, subsequently leading to betterment in fracture impedance and causing an increase of flexural strength [26]. In addition, flexural strength improvement was demonstrated on the base of toughening conversion. While adequate stress was applied and the rift (crack) started to progress, a conversion of TiO2 and Al2O3 from the phase of tetragonal crystal to the phase of stable monoclinic occurred, leading to an energy depletion of crack reproduction. Also, in this operation, an extension or expansion of TiO2 and Al2O3 nanocrystals might occur and submit the crack down a compressive stress state and the crack progression would be stopped. The elevated flexural strength might be resulted from the stress transfer from high resilient polymer to the stiffer nanoparticle filler (higher modulus and higher rigid) [27]. Aljafery et al. found that incorporating alumina and zirconia nanofiller mixture into conventional acrylic resin led to an improvement in flexural strength and statistically highly significant increase [28]. The impact strength was of high value because the shear strength among nanoparticles and the matrix of acrylic resin was high by cross-links formation which led to inhibited crack progression [29]. In addition to the decrease of filler size, the interfacial surface area of all fillers / matrix was abundant for the diffusion of energy raise; hence, the stress for fillers / matrix debonding also rose, which was also considered as a cause of enhanced impact strength [30]. The addition of nanofillers might lead to an efficient network formation, i.e. the three dimensional network of acrylic resin and nanofillers, which further led to decrease of the motion of segment and improvement of the impact strength [31]. This study coincided with findings by Al-Hiloh et al. who added zirconia nanoparticle fillers into acrylic resin of high impact (heat cured denture base) [32].

Conclusions

The incorporation of nanoparticle mixture to acrylic resin (high-impact) material resulted in better flexural resistance and impact resistance of high-impact acrylic resin. The results led to a satisfactory improvement of acrylic denture wearer by prolong clinical service without frequent repairing due to fractures under occlusal forces.

Conflict of Interests

The authors declare that no competing interest exists.

References

Copyright© Ali Mohammad Ali Aljafery. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.