Research Article

Effect of Adding Different Concentrations of CaCO3-SiO2 Nanoparticles on Tear Strength and Hardness of Maxillofacial Silicone Elastomers

Manar Al-Samaray *, Humam Al-Somaiday, Aula Kamal Rafeeq

Department of Prosthodontics, College of Dentistry, Mustansiriyah University, Baghdad, Iraq.

* Corresponding author. E-mail: manaralsamaray@uomustansiriyah.edu.iq

Received: Jan. 5, 2021; Accepted: Aug. 3, 2021; Published: Sep. 4, 2021

Citation: Manar Al-Samaray, Humam Al-Somaiday, Aula Kamal Rafeeq, Effect of Adding Different Concentrations of CaCO3-SiO2 Nanoparticles on Tear Strength and Hardness of Maxillofacial Silicone Elastomers. Nano Biomed. Eng., 2021, 13(3): 257-263.

DOI: 10.5101/nbe.v13i3.p257-263.

Abstract

The service life of a facial prosthesis is about six months as a result of the impairment in its mechanical or physical properties; thus, introducing a new reinforced maxillofacial silicone material can help in fabricating a long service life prosthesis that eliminates the burden for the patients both financially and psychologically. In this study, forty samples were fabricated by adding different concentrations of CaCO3-SiO2 nanoparticles composite to maxillofacial silicone elastomer. These samples were divided into four groups, each one containing ten samples according to the concentration of the fillers (0%,1%,2%, and 3%). All samples were tested for tear strength and hardness tests. The study results show that CaCO3-SiO2 nanoparticles composite has a significant effect on both conducted tests. It can be concluded that reinforcing the silicone matrix with 2% CaCO3-SiO2 nanoparticles composite can improve the tear strength of the tested silicone and increase its hardness.

Keywords: Calcium carbonate, Silicone dioxide, Nanoparticles, Maxillofacial silicone, Tear strength, Hardness

Introduciton

Prosthodontic rehabilitation concerned with restoring both function and natural appearance of patients suffering from facial deformities. According to literature, Polydimethylsiloxane has a wide clinical acceptance [1]. However, its clinical longevity still considered a challenge. Hence, reinforcement of this material may become mandatory to improve its mechanical as well as physical properties [2]. In literature, researchers tried to enhance both the physical and mechanical properties of the maxillofacial silicone to improve the quality of the resultant prosthesis and overcome the reported drawbacks. For example, A-2186 platinum room temperature vulcanized (RTV) silicone, believed to have the best tear resistance among other silicone types in the 1980s, was reinforced by various fillers in an attempt to improve its overall properties. The addition of nylon 6 (PA-6) and tulle (nylon) to A-2186 silicone elastomer improves the tear strength of the modified silicone in a ratio varied with each filler characteristics. Additionally, Titanium (Ti), Zinc (Zn), Cerium (Ce) metal oxides as well as other fillers were also added to this type of silicone material and cause an improvement of the silicone properties [2-4]. After the improvement in the maxillofacial silicone industry and introducing new platinum types like A-2000 and A-2006, researchers still trying their best to study silicone behavior under various conditions after the addition of new additives [5]. All these trials aimed to introduce a silicone material with better tear resistance and clinically accepted hardness value. RTV-4040 is, a new platinum RTV silicone material, recently introduced as one of the best materials dealing with facial replacements. Like other RTV silicones, this material should provide the patient with a natural look. However, the doubtful optimal tear strength of this silicones category is still an obstacle. A-RTV-4040 has very pleasing and promising features; thus working and exploring the two most important properties is the first step toward knowing the exact behavior of this promising material. Surface reactivity, surface energy, and chemical reactivity along with the high surface areas of the nanoparticles made them an excellent additive when trying to improve the silicone properties. The addition of these fillers into silicone matrix controls and improves its characteristics [6]. Calcium carbonate (CaCO3) has a strong interfacial interaction with polymer matrix due to its large surface area in addition to the low aspect ratio [7]. Ikram et al. concluded that adding CaCO3 in trace amounts results in improving some mechanical properties of the silicone elastomer [8]. Silica (SiO2), on the other hand, is one of the most used silicone fillers as a result of its resistance to abrasion, chemical insults, and thermal stimuli [4,9]. Many researchers were interested in adding silica to silicone elastomer. The study of Zayed et al., and Atta allah, and Moudhaffer showed that the incorporation of SiO2 into the silicone matrix increases the service life of the prosthesis [10,11]. Furthermore, the results of Tukmachi and Ali study revealed that SiO2 additives improve all the tested mechanical properties [12]. The use of multiple nano-sized fillers was noticed to produce polymer nanocomposite with better properties when compared to those filled with single micro-scale particles [13]. Cue et al. concluded that the good dispersion of CaCO3-SiO2 into the silicone matrix can improve the mechanical properties of silicone [14]. This study aimed to assess the influence of various concentrations of CaCO3- SiO2 composite addition on tear strength and hardness of A-RTV-4040 facial silicone by answering the following proposed research hypotheses: H0 (the null hypothesis): assumes the addition of various concentrations of CaCO3-SiO2 nanofillers composite does not affect the tear strength and hardness of the tested facial silicone; and H1: The addition of various concentrations of CaCO3-SiO2 nanofillers composite affects the tear strength and hardness of the tested facial silicone.

Experimental

This study investigated tear strength and hardness of A-RTV-4040 silicone elastomer before and after the incorporation of 1%, 2%, and 3% by weight of CaCO3-SiO2 nanocomposite (Table 1).

Table 1 Materials used to prepare the test samples

|

Material |

Manufacturer |

|

A-RTV-4040 silicone elastomer |

Factor II Inc., Lakeside, AZ, USA |

|

CaCO3 powder with an average particle size of 15-40 nm. |

SkySpring Nanomaterials Inc., Huston, TX, USA |

|

SiO2 powder with an average particle size of 15-20 nm |

Nanoshel LLC, Willmington DE, USA |

Samples preparation

The facial silicone was weighed and added over the previously weighed fillers as shown in (Table 2). The mixture then loaded inside the vacuum mixer (Mixyvac t, Manfredi, Italy) container; the mixing procedure started with 3 minutes mixing without vacuum, followed by 7 minutes of vacuum mixing at 360 rpm speed and -10 bar. Another 5 minutes’ vacuum mixing cycle was started after the addition of the silicone catalyst to the silicone base or the modified silicone [12]. The modified silicone then was poured into acrylic molds, made from cutting of 4±0.05 mm, 2±0.05 mm, and 6±0.05 mm thickness acrylic sheets (PT. Margacipta Wirasentosa, Indonesia). These molds were first cleaned with Ethyl Alcohol (Locally market), which left to evaporate, before being wiped with Gypsum separating solution (Isodent spofa, Romania). After 24 hours, complete polymerization of the poured material was obtained and a hundred silicone test samples were fabricated and divided into 4 groups (A, B, C, and D) according to the CaCO3-SiO2 percentage (Table 3).

Table 2 Proportioning of the fillers with the silicone

|

% of CaCO3-SiO2 within the composite |

Wt. of CaCO3-SiO2 (gm) |

Wt. of silicone (Base: Catalyst) (gm) 10 : 1 |

|

|

0% |

0 |

90 |

9 |

|

1% |

0.45:0.45 |

89.1 |

8.91 |

|

2% |

0.9:0.9 |

88.2 |

8.82 |

|

3% |

1.35:1.35 |

87.3 |

8.73 |

Table 3 Test samples' grouping

|

|

Tear strength |

Shore A hardness |

||||||

|

Groups |

A |

B |

C |

D |

A |

B |

C |

D |

|

Fillers proportions |

0% |

1% |

2% |

3% |

0% |

1% |

2% |

3% |

|

Number of samples |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

Testing procedure

Before testing, testing samples were stored for at least 16 hours inside a vaccine storage box (polar bag, china) under favorable conditions (23±2oC and 50±5% relative humidity) [2].

Tear strength test

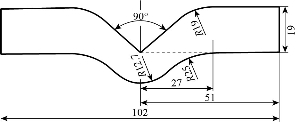

Twenty samples of type C (Fig. 1), un-nicked samples with a 90° angle on one side and with tab end, [15] were mounted in a computerized universal testing machine (WDW-20, Laryee Technology Co., Ltd., China) with a 30±0.5 mm distance apart and 500 mm/min constant rate of separation (tearing strain) without interruption until break [16]. Tear initiation should begin at the stress concentration area located at the 90° apex. If not, the sample was discarded because it will be more indicative of tensile strength. The tear strength was calculated by the machine software according to the following equation: Tear strength = F/D, where F is the maximum force required for a sample to break (kN), and D is the median thickness of each sample (m).

Fig. 1 ASTM D624 type C tear sample (dimensions in mm).

Shore A hardness

Twenty samples of 25×25×6 mm were fabricated [17], shore A durometer (Hardness tester TH200, Beijing Time Technology, China) was adjuster to held vertically over a flat sample supported by a rigid and flat parallel surface with 25±2.5 mm apart. The hardness results were obtained after 1 second of (10) N constant load of the durometer needle penetrating the smooth surface of the test samples. Five readings from 5 points contacts were obtained from each sample with a 6 mm distance between every two points, the average value for each sample was reported as the hardness value [10].

Scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and X-ray diffraction (XRD) analysis

SEM and EDS of the modified silicone were analyzed by scanning electron microscope (Inspect S 50, FEI, USA). While XRD analysis was carried out by X-ray diffractometer (XRD-6000, Shimadzu, Japan).

For both conducted tests (tear strength and shore A hardness), a one-way analysis of variance (ANOVA) was used to assess the differences between the study groups. The mean value of each experimental group was compared using the least significant difference (LSD) post-hoc test. A probability (P) value ≤ 0.01 was considered statistically highly significant (HS). P-value of ≤ 0.05 was considered significant (S), while P-value ˃ 0.05 was considered non-significant (NS). All the data were first computerized then analyzed using IBM SPSS® software (the statistical package for social sciences) version 23.0.

Results and Discussion

SEM, EDS and XRD analysis

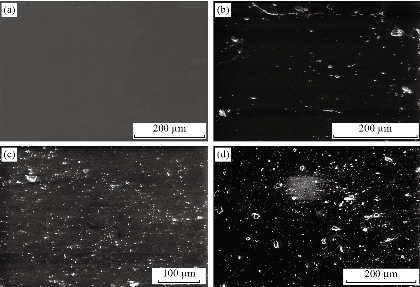

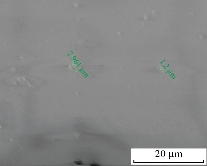

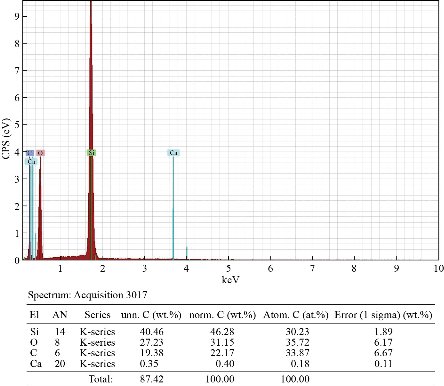

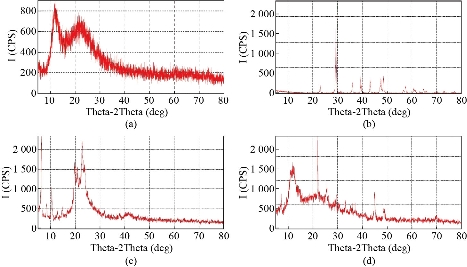

SEM results of A-RTV-4040 silicone elastomer before and after the incorporation of various concentrations of CaCO3-SiO2 nanofillers composite are shown in (Fig. 2). The results indicate a good dispersion of the fillers into the silicone matrix. Furthermore, agglomeration was noticed within the C group more than other study groups. Simultaneously with SEM analysis, an EDS test was conducted to identify the composition of the modified silicone after the incorporation of the filler. EDS peaks indicate the existence of the nanocomposite within the modified silicone elastomer (Fig. 3 and 4). The XRD test was performed to indicates the bonding of CaCO3 and SiO2 in the CaCO3-SiO2 composite. XRD diffraction peaks of A-RTV-4040 facial silicone, CaCO3, SiO2, and lastly the modified silicone is shown in (Fig. 5).

Fig. 2 SEM (magnification × 600) of (a) A-RTV-4040 silicone elastomer, (b) A-RTV-4040 silicone elastomer filled with 1% CaCo3:SiO2, (c) A-RTV-4040 silicone elastomer filled with 2% CaCo3:SiO2, and (d) A-RTV-4040 silicone elastomer filled with 3% CaCo3:SiO2.

Fig. 3 SEM of A-RTV-4040 silicone elastomer filled with 2% CaCo3:SiO2

(magnification × 5000).

Fig. 4 EDS of the modified silicone.

Fig. 5 XRD of (a) A-RTV-4040 silicone elastomer, (b) CaCo3, (c) SiO2, and (d) modified silicone.

Tear strength

Statistical analysis for tear strength test (kN/m) revealed a highly significant increase (𝑃 < 0.001) in the tear value of various concentrations fillers’ groups when compared to the control group (Table 4).

Table 4 Descriptive statistics, one-way ANOVA and LSD of tear strength test (kN/m)

|

LSD |

P-value |

ANOVA F- test |

D |

C |

B |

A |

|

|||

|

Sig. |

P-value |

Compared groups |

||||||||

|

HS |

≤ 0.001* |

B |

A |

|||||||

|

HS |

≤ 0.001* |

C |

≤ 0.001 (HS) |

2358.129 |

5 |

5 |

5 |

5 |

N |

|

|

HS |

≤ 0.001* |

D |

28.07 |

36.83 |

33.99 |

19.45 |

Mean |

|||

|

HS |

≤ 0.001* |

C |

B |

0.15 |

0.5 |

0.44 |

0.15 |

SD |

||

|

HS |

≤ 0.001* |

D |

27.86 |

35.96 |

33.64 |

19.3 |

Min. |

|||

|

HS |

≤ 0.001* |

D |

C |

28.23 |

37.19 |

34.69 |

19.7 |

Max. |

||

* Highly significant difference compared to test groups (P ≤ 0.001)

Shore A hardness

The results for shore A hardness test (IU) also showed a highly significant increase (𝑃 < 0.001) of the hardness test when compared to the control group (Table 5).

Table 5 Descriptive statistics, One-way ANOVA and LSD of Shore A Hardness test (IU)

|

LSD |

P-value |

ANOVA F- test |

D |

C |

B |

A |

|

|||

|

Sig. |

P-value |

Compared groups |

||||||||

|

HS |

≤ 0.001* |

B |

A |

|||||||

|

HS |

≤ 0.001* |

C |

≤ 0.001 (HS) |

21.532 |

5 |

5 |

5 |

5 |

N |

|

|

HS |

≤ 0.001* |

D |

45 |

43.4 |

42.8 |

40.2 |

Mean |

|||

|

NS |

0.339‡ |

C |

B |

0.707 |

0.894 |

0.447 |

1.483 |

SD |

||

|

S |

0.002† |

D |

44 |

42 |

42 |

38 |

Min. |

|||

|

S |

0.018† |

D |

C |

46 |

44 |

43 |

42 |

Max. |

||

* Highly significant difference compared to test groups (P ≤ 0.001);

† Significant different compared to test groups (P ≤ 0.05);

‡ Non-significant difference compared to test groups (P > 0.05).

Discussion

This study aimed to enhance some mechanical properties of a newly developed silicone material to achieve a long-lasting prosthesis. To accomplish this, a composite of different concentrations of 1:1 (CaCO3-SiO2) were added to the tested silicone material, the modified silicone was tested for tear strength and shore A hardness tests. In this study, A-RTV-4040 as a recently introduced pourable, high molecular weight platinum RTV silicone material with 50.000 cps viscosity, CaCO3 with its strong interfacial interaction with polymer matrix, and the SiO2 as one of the most used silicone fillers that enhance the polymer adsorption by the nano silica’s large surface area were chosen to be tested. Furthermore, tear strength and hardness were selected to be evaluated because they have a great impact on the resultant prosthesis, especially on the thin margins, where high strength value and acceptable clinical hardness are preferred [18]. The saturated form of silicone elastomer, from a chemical respective, has no functional group to react with, therefore; this research tried to form a physical blend (changing the geometry of the silicone) that may end up with a material with better properties. To confirm this, EDS in addition to XRD analysis was performed to assure the incorporation of the fillers and the formation of a 3-D network within the silicone matrix. The characteristic peaks of calcite and the characteristic bulged peaks in the modified silicone XRD view indicates the bonding of CaCO3 and SiO2 in the CaCO3-SiO2 composite (Fig. 4 and 5). The mechanical and physical properties of the resultant material may have affected by the fillers' concentration, fillers' size, and fillers' loading. The results of the statistical analysis depict a highly significant improvement (P ≤ 0.001) in the tear strength of the tested silicone elastomer when incorporated with CaCo3-SiO2 nano-particles, noticing that the values of the experimental group (C) were found to be significantly higher than other study groups (Table 4). This improvement may be due to the increase in the surface area at nano-scale which in turn enhanced the adsorption of the polymer. The mixed nanocomposites appear to have smaller agglomerates in Group C when compared to other experimental groups which may be the results of the narrow size-distribution of CaCO3-SiO2 composite, which is less than 5 µm in size that contributes in enhancing the silicone properties more than the other experimental groups. When the filler concentration increased to 3% CaCO3-SiO2, the surface energy, and chemical reactivity were increased too. This increase results in the agglomeration of the nano-sized particles [19]. This agglomeration works as stress concentrating centers in the silicone matrix which decreases the tear strength value under external forces (Fig.2 and 3). The flexibility (hardness) of the modified silicone elastomers was increased as the nanofillers loading was increased from 1% to 3% (Table 5). This can be explained by the fact that increasing the filler concentration reduces the mobility of the polymer chains by increasing polymer-filler interactions. Furthermore, the nanoparticle incorporation into the silicone matrix reduces the material polymerization rate by hindering the twisted polymer chains [18, 20]. Based on that, the null hypothesis that the addition of various concentrations of CaCO3-SiO2 nanofillers composite does not affect the tear strength and hardness of the tested facial silicone was rejected. Since the development in material science in general, and the nanotechnology in particular, may cause a qualitative leap in the future development of prosthodontic technology, future researches should focus not only on developing new nano-sized composite materials but also on the behavior of these materials under variable conditions.

Conclusions

Incorporating the silicone matrix with a 2% CaCO3-SiO2 improved the tear strength of the modified silicone. The hardness of the modified silicone was directly proportional to the increase in the fillers loading concentrations.

Acknowledgements

The authors would like to thank Mustansiriyah University (www.uomustansiriyah.edu.iq) Baghdad- Iraq for its support in the present work.

Conflict of Interests

The authors declare that no competing interest exists.

References

Copyright© Manar Al-Samaray, Humam Al-Somaiday, and Aula Kamal Rafeeq. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.